CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

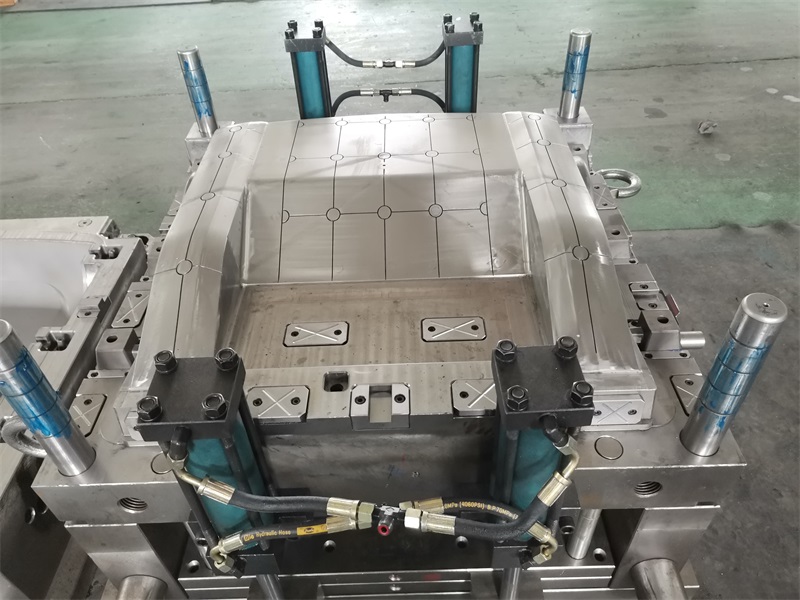

Plastic injection mold for new design fitness equipment gym exercise equipment parts

Our company have nearly10 years of experiencein in plastic injection molding design and manufacturing processing. We utilize and invest in new technology and have a highly skilled mould designing and making team.If you are interested in our ....

Send InquiryLatest Articles

- Plastic trashcan mould injection process

- Common failure reasons and troubleshooting methods for injection molds

- How long does it take for Plastic Mold Factory to make plastic molds?

- What should be paid attention to when processing plastic molds

- what are the common problem in the plastic mould injection process

- How to check the test of the injection mould