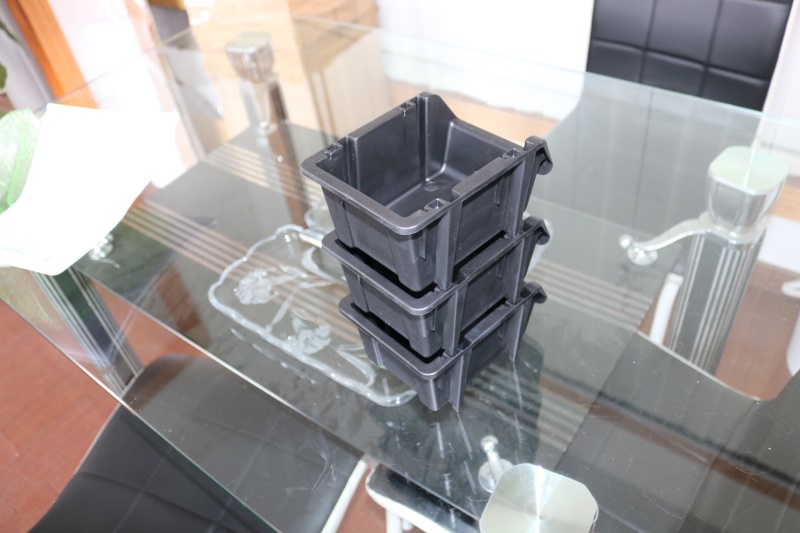

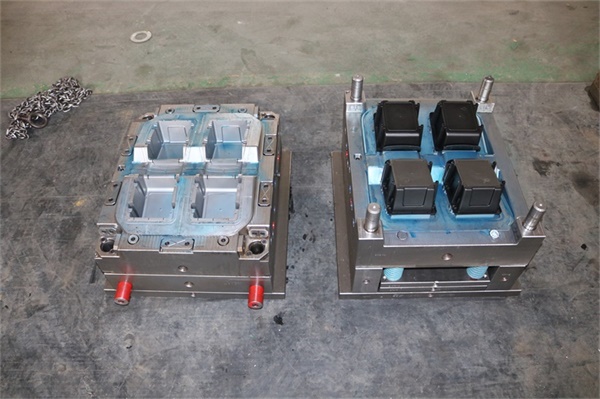

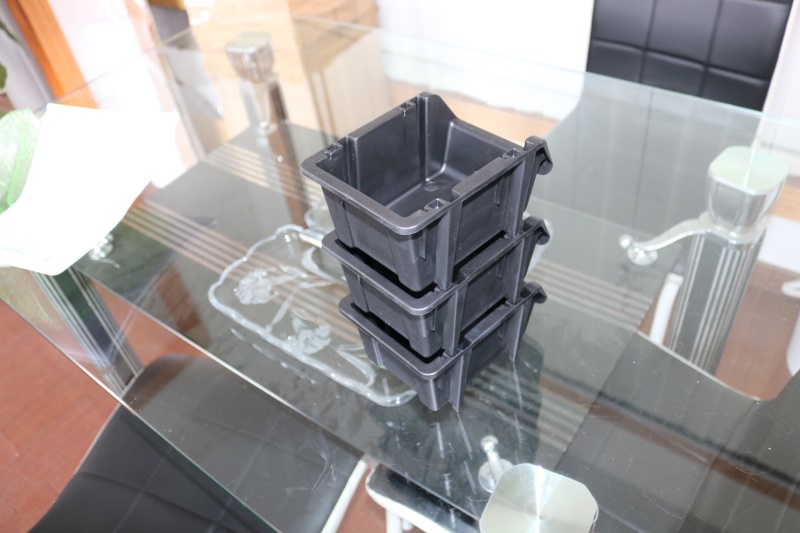

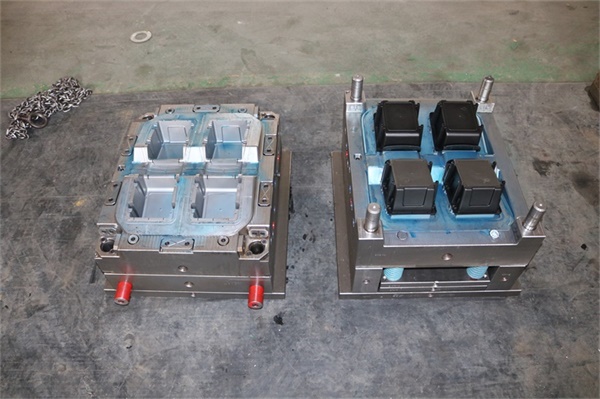

Plastic Storage Stacking Hanging tool box mould factory process production and process

In recent years, the toolbox industry has higher and higher requirements for mechanical equipment and instruments! The cost of mold testing equipment, three-coordinate detectors and other testing instruments is constantly increasing, which shows that the improvement of quality is the direction of the toolbox manufacturers' needs. After more than 20 years of exploration and continuous learning, Haichuan Mould Co., Ltd. has summed up many years of experience: To ensure the quality of the toolbox production, it is also necessary to strictly control the key links of the production and production of the toolbox. Quality, specific conditions can be controlled from the following 9 steps:

1. Useful for product data processing, process data processing, drawing document processing

2. The planning and forming costs of each set of molds need to be summarized in a timely manner.

3. Adhere to the consistency and integrity of the data of the mold drawings, processing technology, and materials: After useful, detailed and rigorous testing methods, ensure the consistency and integrity of the data of mold drawings, processing technology, and materials

4. Overall planning: organically organize and integrate the information of the scheme, plan, processing technology, workshop production status, human resources, etc. for overall planning

6. Establish processing technology.

7. Establish the quality inspection part to ensure the precision of each part of the mold processing.

8. According to the situation of the company and the customer, draw up suitable mold planning standards and mold planning instructions for the company and the customer.

9. Set up a follow-up processing team for the mold project: set up a bridge for communication and supervision between customers-shopping malls-engineering-acquisition-production-warehouse-injection molding and other parts.

With the gradual fullness of the toolbox mall, the demand for the mall is getting smaller and smaller, and the functional requirements and personalization requirements of the products are getting higher and higher. Plastic Storage Stacking Hanging tool box mould,The era of the toolbox winning with low prices has gone forever. The development slogan sounded. Hundreds of thousands of new technology start-up companies participated in the mall. In addition to technological innovation and breakthroughs, the quality requirements for all aspects of the product were more stringent than in the past. This also promoted the entire manufacturing operation Quality reform, as the mother of industry, opportunities and challenges coexist on the cusp of the wind. As long as we strive for excellence, introduce advanced equipment, and complete a more complete processing mechanism. Talent can control the quality of the toolbox in the link, as long as this talent is more useful to improve the quality of the mold. Keeping pace with technology, we can make our products better meet the needs of shopping malls.

Hot Tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker, customized

CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882