CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

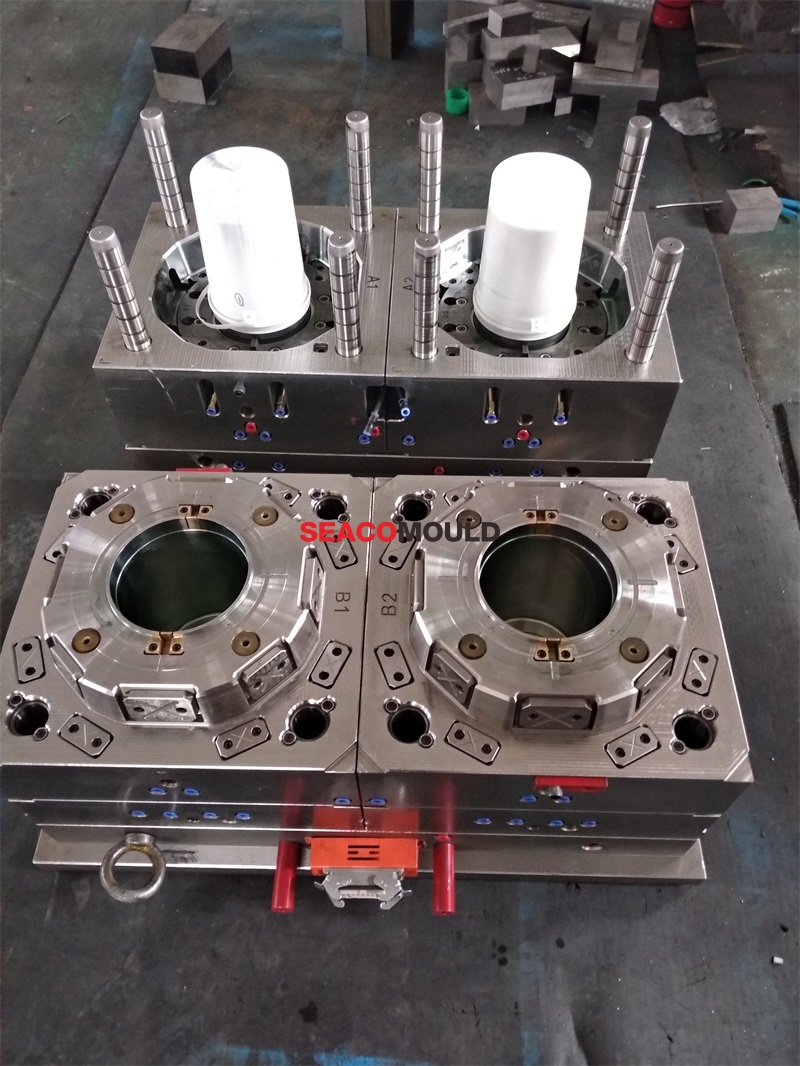

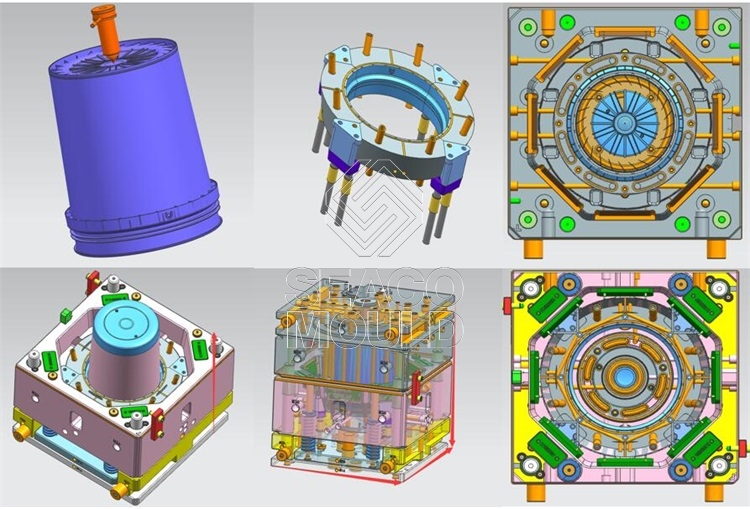

Plastic food container bucket mold 2cavity icecream bucket mold

Seaco Mould is professional OEM custom plastic mould, we focuses on quality and on time delivery.we have exported more than 100sets bucket and container moulds each year to our customers. We have built long term relationship and thanks for o....

Send InquiryLatest Articles

- Plastic trashcan mould injection process

- Common failure reasons and troubleshooting methods for injection molds

- How long does it take for Plastic Mold Factory to make plastic molds?

- What should be paid attention to when processing plastic molds

- what are the common problem in the plastic mould injection process

- How to check the test of the injection mould