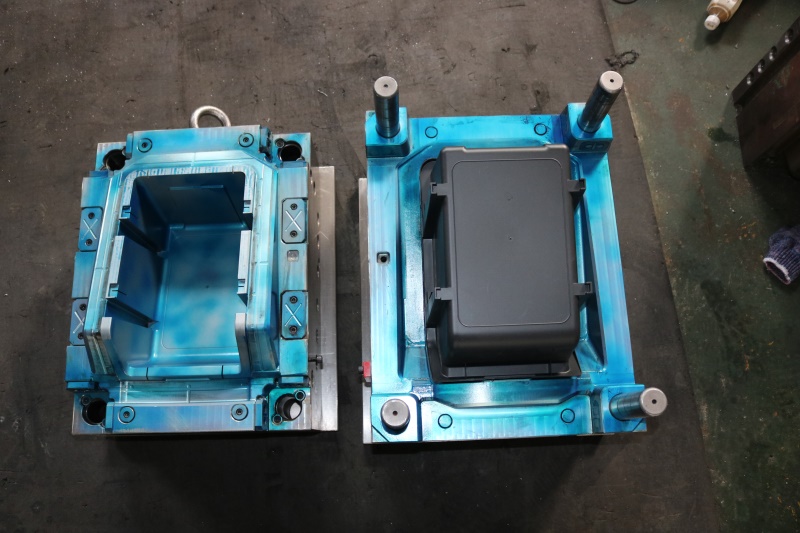

Plastic toolbox mold manufacturer, supply toolbox mold price, mold toolbox company, mold toolbox wholesale, mold toolbox picture, mold toolbox specifications and more.

How to ensure toolbox mold quality

Adopt foreign advanced hot runner technology, combined with the needs of domestic customers, adopt shear-free gate design, the hot runner nozzle controls the temperature independently. The molds are produced under fully automatic conditions, eliminating the need for frequent staff operations to reduce labor intensity. Production of various PET hot runner bottle cap molds: ordinary long gates, ordinary short gates, air-sealing self-locking adjustable non-gates, etc., a new preform mold structure completely developed independently, completely abandoning the former department Disadvantages, it is possible to achieve high-precision concentricity of the mold, standardization of various parts of the mold, and large-scale production.

Taizhou Haichuan Mould Factory's advanced design technology is guaranteed by excellent special processing equipment and perfect testing methods. In addition to the advantages, it also has the following important features: reliable and reliable, heat preservation and energy saving, convenient and reliable device, light weight, high strength, heat resistance, low pressure loss, and raw materials can be recycled.

Matters needing attention for toolbox mold manufacturing?

Only focus on product design and neglect mold production— (plastic bag punching machine, pneumatic punching machine, plastic bag punching machine, bag making machine punching machine).

How to take the stubborn finished product remaining in the mold

How to take the remaining product in the mold and stubborn product 1. Use a brass piece to squeeze into the crack between the product and the mold, and pry to make the product leave the mold cavity, but apply this method to non-ferrous alloy molds. 2. In order to achieve this goal, new injection mold technology should be provided on the injection molding machine (for example, 3mm thick, 300MM wide, and the front end is molded into a knife shape). The development and application of new mold technology is to develop Is biased towards new mold technology, the development and application of new mold technology is today ...

Some users are often focusing on product research and development at the initial stage of developing toolbox molds or neglecting to communicate with the mold making unit. After the product design plan is initially determined, there are two advantages to contacting the mold manufacturer in advance:

First, the product that can be guaranteed to be designed has a good forming process, and it will not be fixed and shaped due to the difficult processing of parts.

Second, the mold making can do the design preparation in advance, in case of rush consideration, which will affect the construction period.

In short, to produce high-quality toolbox molds, only when the supply and demand sides are carefully co-operated, the talent is ultimately reduced, and the cycle is shortened.

Don't just look at the cost, you must consider all aspects of quality, cycle and service-plastic bag punch, pneumatic punch, plastic bag punch, bag making punch.

There are many types of toolbox molds, which can be divided into ten categories. According to the different requirements of part materials, physical and chemical properties, mechanical strength, dimensional accuracy, surface finish, application life, economy, etc., the mold forming of different examples is selected.

High-precision molds must be processed with high-precision CNC machine tools, and mold materials and forming processes have strict requirements. CAD / CAE / CAM mold technology must also be used for design and interpretation. Because some parts have special requirements during molding, the mold also needs to apply excellent processes such as hot runner, gas-assisted molding, and nitrogen cylinder. The production plant should have CNC, EDM, wire cutting machine tools and CNC copy milling construction, high-precision grinding machines, high-precision three-coordinate measuring instruments, computer design and related software. For ordinary large stamping dies (such as automobile cover molds), it is necessary to consider whether the machine tool has a blank holder mechanism, or even a side lubricant, and multi-stage progressive. In addition to stamping tonnage, punching times, feed assembly, machine tool and mold guard assembly must be considered.

Toolbox mold mold production methods and processes are not owned and mastered by every enterprise. When selecting a cooperative factory, it is necessary to inquire about its processing ability, not only looking at the hardware building, but also connecting the management level, processing history and technical strength.

Occasionally, there are very large differences in the prices for uniform sets of molds. You shouldn't pay more than the cost of the mold, and it shouldn't be less than the original cost of the mold. The mold factory, like you, wants to make a reasonable profit in the business. Customizing a set of molds with much lower quotes can be a difficult start. The user must develop the "full scale" from his own requirements.

Avoid multi-head collaboration ‚despite the one-stop of mold making and finished product processing-plastic bag puncher, pneumatic puncher, plastic bag puncher, bag making machine puncher.

With a passing toolbox mold (passing of the test specimen), it is not necessarily possible to produce a batch of passing products. This is mainly related to the selection of the machine tool for the part, the forming process (forming temperature, forming time, etc.) and the nature of the operator's craftsmanship. With a good mold, but also a good forming process, very good is a one-stop collaboration, although avoiding multi-head collaboration. If the conditions are not met, one party must be selected to take full responsibility, and it must be clearly written when the treaty is concluded.

What are the main factors affecting the toolbox mold? Why is the mold temperature of the mold temperature machine very nervous for high-gloss injection molding?

What are the main components that affect the mold? Why is the mold temperature master of the mold temperature machine very nervous for high-gloss injection molding? The highlight of the high-temperature injection mold temperature machine is the mold temperature control system. Because the difference between high-gloss injection molding and ordinary injection molding lies in the control of the mold temperature, the requirements for the injection molding machine are not high. The high-gloss injection mold temperature mastering system is also commonly known as the high-gloss mold temperature machine. It is jointly operated with a general-purpose injection molding machine to reconcile actions during the process of filling, maintaining, cooling, and opening and closing the mold.

Hot Tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker, customized

CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882