CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

Bottle cap mold manufacturing process

2020-02-02

Development direction of bottle cap mold manufacturing process

The development of the bottle cap mold manufacturing industry is an industrial industry that integrates multi-professional and multi-disciplinary knowledge and serves multiple processing fields. The use of bottle cap molds to produce products has a series of advantages such as high efficiency, good quality, saving energy and raw materials, and low cost. Mold has become an important means and processing technology of modern industrial production. With the development of science and technology and social economy, the product development cycle and product update period are gradually shortened, and the use of molds has become more frequent and has penetrated into various industries. Applications are particularly widespread. As an industry, the development and prosperity of the mold industry is an important sign of the development of modern industrial technology. The development of most industrial products and the improvement of technological level depend to some extent on the development level of the mold industry. Has been very clearly reflected in the industrial history.

Since the 1980s, the development of science and technology, especially the rapid development of computer application technology, has had a significant impact on the development of the bottle cap mold industry. As computer-aided design, auxiliary manufacturing, and auxiliary analysis have been generally introduced into the field of mold manufacturing, mold CAPP and CIMS projects have begun to achieve results in some enterprises, and fundamental changes have taken place in bottle cap mold manufacturing technology. Now, transmitting mold information through the Internet, and controlling mold production from a distance has become an important business method for some enterprises. The shortening of mold production cycle, quality improvement and cost reduction have made the overall level and technological content of mold manufacturing a qualitative leap. In recent years, rapid prototyping manufacturing technologies such as laser three-dimensional modeling (SLA), layered solid manufacturing (LOM), selective laser sintering (SLS), and molten deposition manufacturing (FDM) have developed rapidly. New technologies are constantly emerging and mold manufacturing Technology is in a very active development phase.

Bottle cap mold manufacturing process method

Bottle cap mold is the most widely used tool product in the manufacturing industry. Mold manufacturing has become an important part of advanced manufacturing technology. Because the cavity of the mold is mostly composed of complex curved surfaces, CNC machining is a heavy task when processing on high-speed CNC machine tools. The quality of the programming largely determines the machining quality of the mold parts.

The main factors that affect the programming quality of bottle cap mold parts are: processing technology route, tool type, cutting method and direction, cutting amount, corner clearing treatment, and processing accuracy and overcut inspection. High-speed processing technology is the main factor affecting the quality of mold manufacturing. Whether the processing technology is reasonable in the past depends entirely on the personal experience of the programmer. If you are not careful, you will often ignore some technical details, such as the incorrect cutting point, insufficient lifting height, unsatisfactory cutting method, no overcut inspection surface, etc. . If the review is not rigorous in the trial processing and is not corrected in time, the lighter will cause cutting, reduce the mold manufacturing quality, and cause the workpiece to be reworked; the heavy one will cause the workpiece to be scrapped, and even a personal equipment accident will occur.

Without cavity molds, die-casting dies, casting dies, deep-drawing dies and stamping dies, it is impossible to produce widely used and competitively priced plastic parts, alloy die-casting parts, steel plate parts and forgings. In modern mass production, without high-level bottle cap molds, there can be no high-quality products. It also plays an important role in improving production efficiency and reducing production costs. The materials used to make molds are usually difficult to process. At present, domestic mold cavities generally use EDM and high-speed processing technologies. In modern processing technology, the mold manufacturing industry was the first to apply computer technology to improve the design and manufacturing level. Since the introduction of modern high-speed processing technology into the bottle cap mold manufacturing industry, computer-aided design (CAD), computer-aided measurement (CAT), reverse engineering (RE), computer-aided engineering (CAE), computer-aided manufacturing (CAM), and rapid Prototype manufacturing (RP) has been widely and effectively used in mold manufacturing.

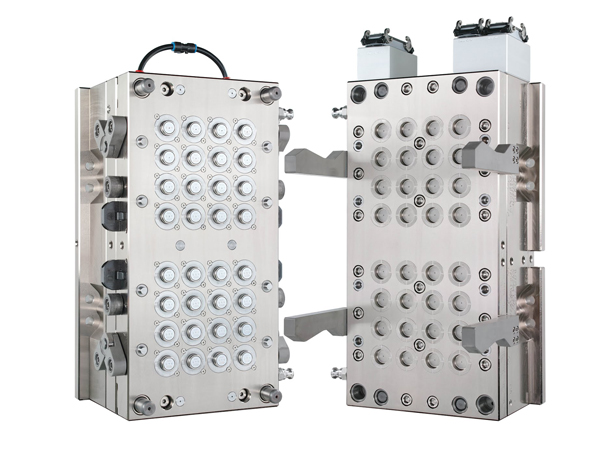

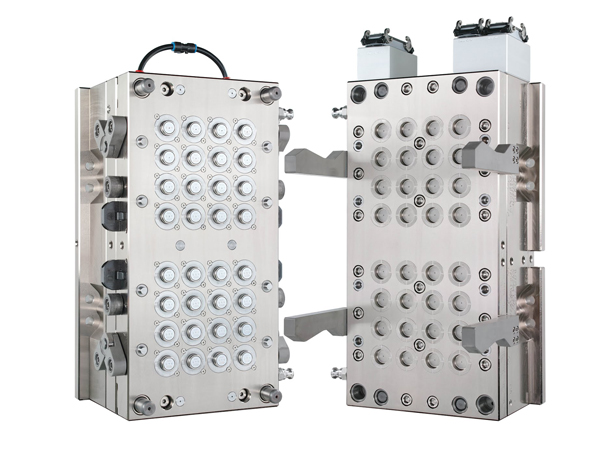

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould

Hot tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker,customized