CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

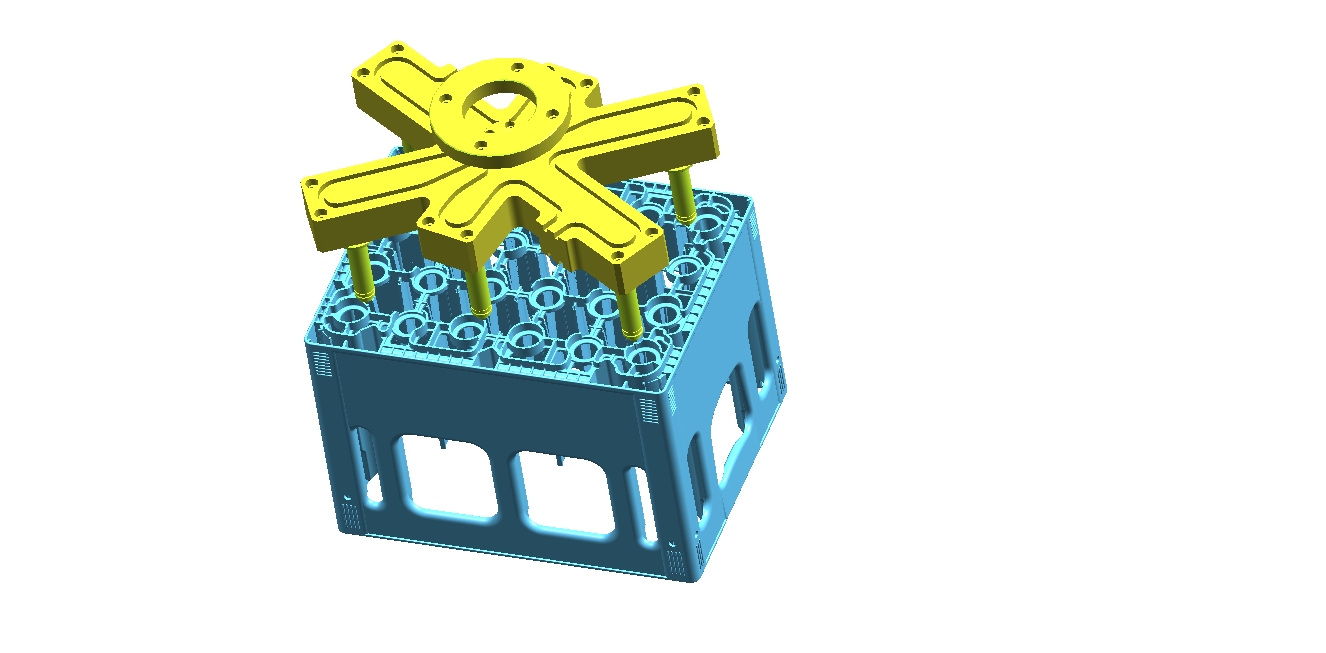

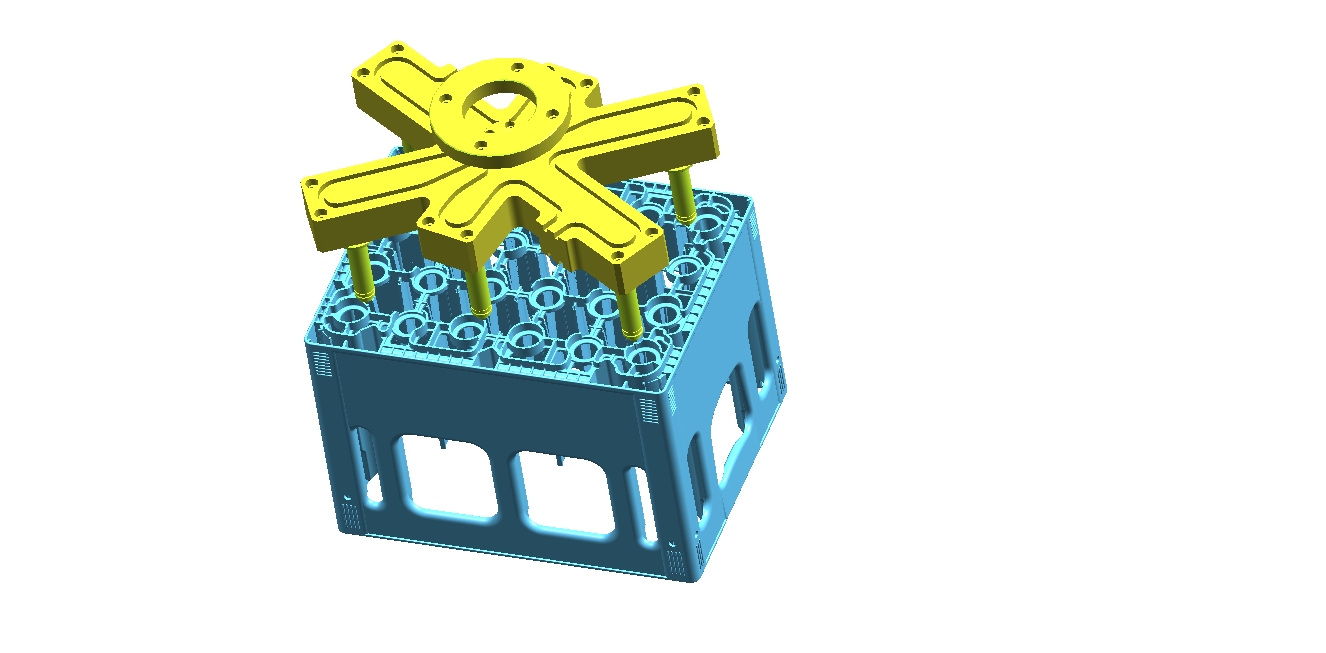

How to make the injection plastic mould gate design

2019-11-16

The design of the mould gate is related to the size of the plastic part, the shape of the mold, the injection process conditions and the performance of the plastic mould part. However, in terms of basic functions, the gate section is small and the length is short, because only in this way can the requirements of increasing the flow rate, rapid cooling and closing, and the separation of the plastic parts and the minimum gate residue are satisfied.

Chinese plastic mold manufacturers summarized the gate design points as follows:

- 1) The choice of gate location should minimize the plastic filling process to reduce pressure loss;

- 2) The choice of gate location should be beneficial to eliminate air in the cavity;

- 3) The gate should be opened as far as possible without affecting the appearance of the plastic part, such as the bottom of the edge;

- 4) The size of the gate depends on the size, shape and plastic properties of the plastic part;

- 5) The gate is opened in a thick section of the plastic part, so that the molten material flows from the thick material section into the thin section to ensure complete filling;

- 6) When forming large or flat plastic parts, a double gate can be used to prevent warpage, deformation and lack of material;

- 7) When designing multiple cavity injection molds, consider the balance of the flow channels to consider the balance of the gates, and try to make the molten materials uniformly charge at the same time.

- 8) The gate should not be allowed to flush the melt straight into the cavity, otherwise it will produce a swirling flow, leaving traces of the rotation on the plastic part, especially the narrow gate is more prone to such defects;

- 9) The choice of gate location should prevent the formation of seam lines on the plastic surface, especially in circular or cylindrical plastic parts. The cold well should be added at the melt casting of the surface of the gate. ;

- 10) The gate position of the injection mold with the elongated core should be far from the forming core, so that the forming core is not deformed by the flow;

- The company has professional engineering and technical personnel and advanced precision testing equipment, mainly injection molding products: household appliances, communication products, displays, computer peripheral products, clock gears, CD machine products; set-top box terminals, plastic products, transparent parts and other high Precision plastic fittings. All products have strict quality management and professional technical level from design to molding.

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

- What should you pay attention to when designing injection molds

- Corner treatment of mold parting surface for automotive mold design

- Why does the bumper mold adopt the internal fractal structure design

- Key points of plastic mold design

- Design and development of medical equipment and product molds

- Design of Multi-cavity Injection Bottle Cap Mould

- Considerations for the design of plastic bottle cap moulds

- Structural design of beverage bottle cap mold

- Leak-proof design of bottle cap mould

- What are the structural elements to be considered in plastic mold design

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould

Hot tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker,customized