CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

What are the structural elements to be considered in plastic mold design

2019-12-21

Plastic mold design is based on correct plastic product design. Mold design and manufacturing are closely related to plastic processing. The success or failure of plastic processing largely depends on the effect of mold design and mold manufacturing quality.The structural elements that need to be considered in plastic mold design are the following:

1. Parting surface, that is, the contact surface of the concave mold and the convex mold when the mold is closed. The choice of its location and form is affected by factors such as product shape and appearance, wall thickness, molding method, post-processing technology, mold type and structure, demolding method, and molding machine structure.

2. Structural parts, that is, sliders, inclined tops, and straight top blocks of complex molds. The design of structural parts is very critical, which is related to the life of the mold, processing cycle, cost, product quality, etc. Therefore, designing the core structure of a complex mold has higher requirements on the designer's comprehensive ability. Design.

3, mold accuracy, that is, avoiding cards, precise position fixation, guide posts, position fixing pins, etc. The position fixing system is related to the appearance quality of the product, the quality of the mold and the life.According to the different mold structures, different position fixing methods are selected.The control of the position fixing accuracy mainly depends on processing. Easy to adjust position fixing method.

4, the pouring system, that is, the injection channel from the injection molding machine nozzle to the cavity, including the main flow channel, the flow channel, the gate and the cold material cavity. In particular, the location of the gate should be suitable for the molten plastic to fill the cavity in a good flowing state. The solid runners and gate cold materials attached to the product are easy to eject from the mold and be removed when the mold is opened (heat flow Except Daomo).

5, plastic shrinkage and various factors affecting the dimensional accuracy of products, such as mold manufacturing and assembly errors, mold wear and so on. In addition, when designing compression molds and injection molds, the matching of process and structural parameters of the molding machine should also be considered.

When gas is injected into plastic products, it will directly affect the quality of the product. The product will have loose structure and reduced strength, and it will easily form marks, air marks, and weld marks on the surface, which will cause high residual stress inside the plastic product and easily form Welding marks not only affect the appearance, but also affect the marks at the weld, reducing the impression score of people on the product from the aspect of appearance.

If it is during the injection molding process, local edge separation will occur. If the gas cannot be eliminated, it will cause the injection pressure to increase, forming a product flash. If there is gas during the melt filling, it will reduce the melt filling speed. , The molding cycle increases, resulting in local carbonization of plastic products.

Due to the effects of trapped air that affects the quality of processing, technical adjustments need to be made from the processing link in order to solve the processing defects. The phenomenon of trapped air is mainly due to poor exhaust. There is inherent air in the cavity. It is necessary to exhaust the air. If the exhaust is not good, it will be trapped. In addition, the injection speed is too fast. If the gas is too late to exhaust, it will also be trapped. Less.

Our company's management policy is based on quality over life. Taking innovation as the distance, keeping improving as the business philosophy. The company's mission is to develop itself and contribute to society, and strive to create a more beautiful tomorrow.

1. Parting surface, that is, the contact surface of the concave mold and the convex mold when the mold is closed. The choice of its location and form is affected by factors such as product shape and appearance, wall thickness, molding method, post-processing technology, mold type and structure, demolding method, and molding machine structure.

2. Structural parts, that is, sliders, inclined tops, and straight top blocks of complex molds. The design of structural parts is very critical, which is related to the life of the mold, processing cycle, cost, product quality, etc. Therefore, designing the core structure of a complex mold has higher requirements on the designer's comprehensive ability. Design.

3, mold accuracy, that is, avoiding cards, precise position fixation, guide posts, position fixing pins, etc. The position fixing system is related to the appearance quality of the product, the quality of the mold and the life.According to the different mold structures, different position fixing methods are selected.The control of the position fixing accuracy mainly depends on processing. Easy to adjust position fixing method.

4, the pouring system, that is, the injection channel from the injection molding machine nozzle to the cavity, including the main flow channel, the flow channel, the gate and the cold material cavity. In particular, the location of the gate should be suitable for the molten plastic to fill the cavity in a good flowing state. The solid runners and gate cold materials attached to the product are easy to eject from the mold and be removed when the mold is opened (heat flow Except Daomo).

5, plastic shrinkage and various factors affecting the dimensional accuracy of products, such as mold manufacturing and assembly errors, mold wear and so on. In addition, when designing compression molds and injection molds, the matching of process and structural parameters of the molding machine should also be considered.

What happens to the trapped plastic mold design during processing

In the process of using any product, some problems will inevitably occur in China. Of course, plastic mold processing machinery is also the same. We will teach you some tricks to solve the problem of trapped air that often occurs in molds.When gas is injected into plastic products, it will directly affect the quality of the product. The product will have loose structure and reduced strength, and it will easily form marks, air marks, and weld marks on the surface, which will cause high residual stress inside the plastic product and easily form Welding marks not only affect the appearance, but also affect the marks at the weld, reducing the impression score of people on the product from the aspect of appearance.

If it is during the injection molding process, local edge separation will occur. If the gas cannot be eliminated, it will cause the injection pressure to increase, forming a product flash. If there is gas during the melt filling, it will reduce the melt filling speed. , The molding cycle increases, resulting in local carbonization of plastic products.

Due to the effects of trapped air that affects the quality of processing, technical adjustments need to be made from the processing link in order to solve the processing defects. The phenomenon of trapped air is mainly due to poor exhaust. There is inherent air in the cavity. It is necessary to exhaust the air. If the exhaust is not good, it will be trapped. In addition, the injection speed is too fast. If the gas is too late to exhaust, it will also be trapped. Less.

Our company's management policy is based on quality over life. Taking innovation as the distance, keeping improving as the business philosophy. The company's mission is to develop itself and contribute to society, and strive to create a more beautiful tomorrow.

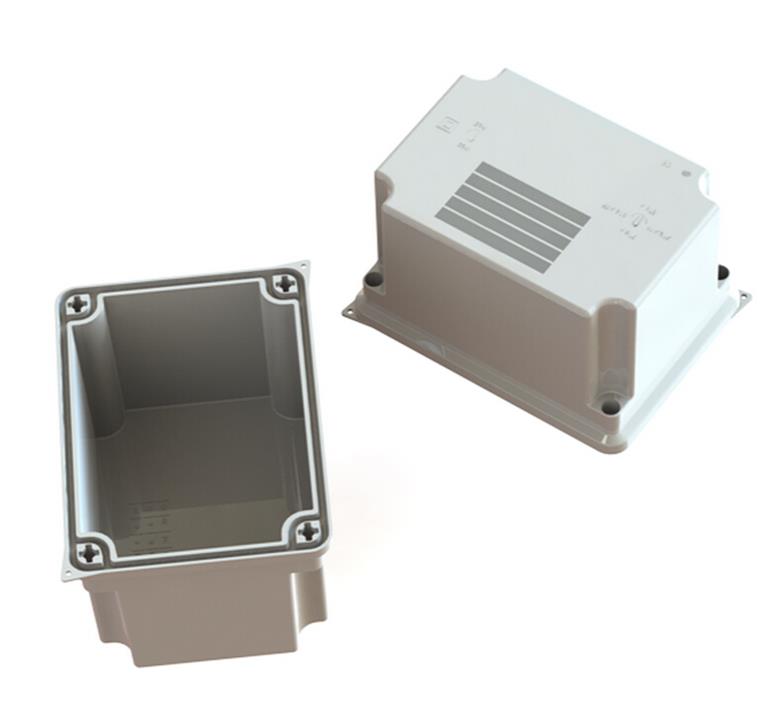

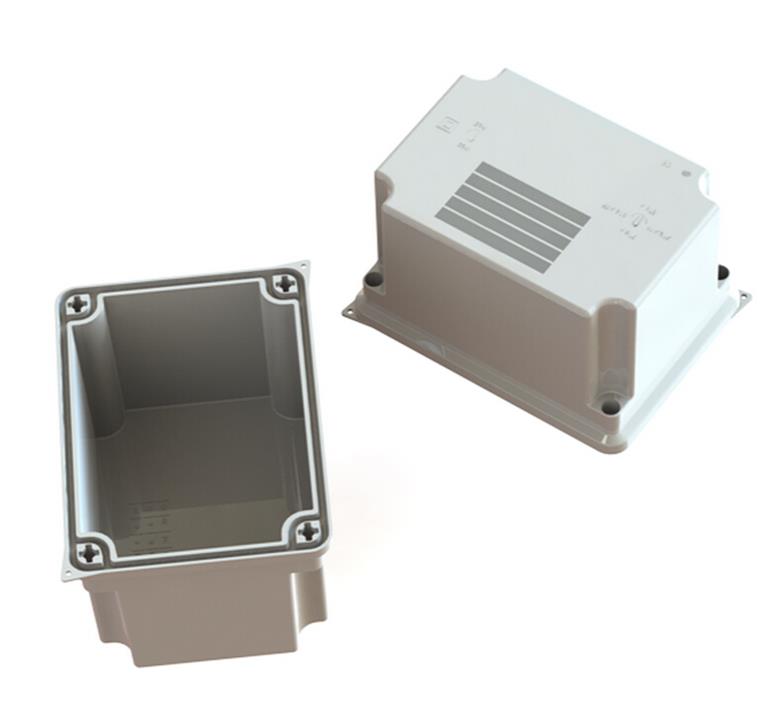

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould

Hot tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker,customized