CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

How to make plastic bucket mould

2019-12-14

|

|

Plastic bucket mold is one of our most important plastic injection mold, our bucket mold includes thin wall bucket mold, food bucket mold, pail mold, cylinder bucket mold, square shape bucket mold,cuboid bucket mold, industrial use bucket and pail mold, water bucket mold, industrial paint bucket mold, fishing bucket mold, packing bucket mold, dustbin bucket mold,cement pail mold, plastic barrel mold and other bucket molds.

-

Material of the plastic bucket.

PP PE -

The material of the bucket mould.

Choose 718 steel is most popular for bucket mould, long mould life and god prefermance, high-grade forged tool steel relatively free fo defacts; it is available in a prehardened steel. It can be textured or polished to almost any desired finish and it is a tough material. Also P20 Iis another wide used bucket mould steel,300000-500000 shots mold life avaliable, And of course if you made bucket mould before, you will know that, bucket mould often inserted with Becu(beryllium copper) for reduce cooling time, is used to meed specific requirements to meet tool life and cost. Where for higher degree of the mould ,you can choose 2344 with becu insert, and S136,very good choice, but expensive. -

Bucket mould runner system.

Plastic bucket mould usd hot runner is mainly point gate and direct gate, for the handle hot runner is better to do more cavities. -

Bucket mould ejection system.

Usually ejection by stripper plate and air.

How to make design of plastic bucket mould

In order to produce high quality barrel mould, attention should be paid to the details of many links, and the most important of these is the following three points:

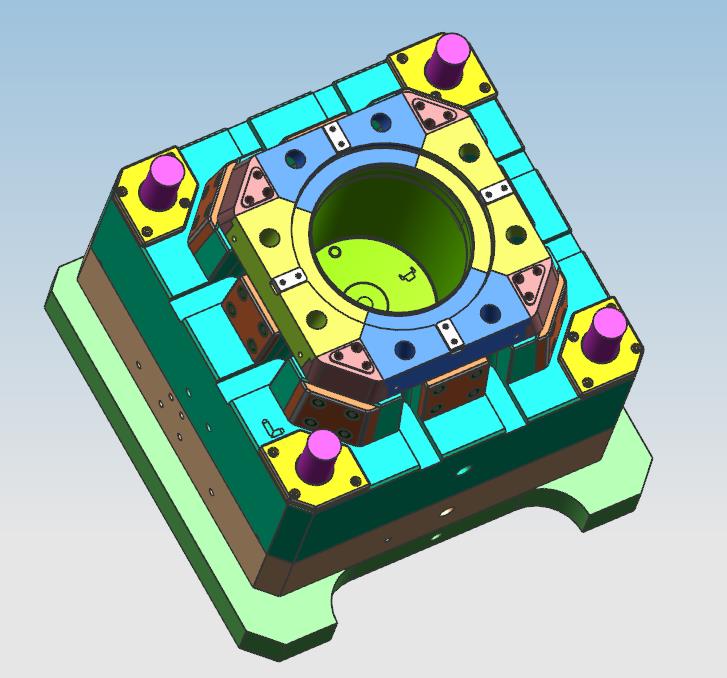

1. Bucket Mould Design and Structure

A high-quality mold structure is a premise for a qualified plastic bucket mold. We attach great importance to analyze mold structure, including demolding draft angle, the epitome of product surface, gating system design, exhaust design, cooling system design, etc.The main problems that may easily occur will through trial and error during the mold structure design.

2. Bucket Mould Material

In order to improve the mold life and product quality, we increase the mold steel hardness through heat treatment. The steels we commonly use are H13(48-52HRC), 2316(45-50HRC) etc.to prevent mold eccentric, we use whole piece of steel to make the bucket. The cooling system is very important. We adopt single loop cooling way and setup even distribution water channels as much as possible. All small sliders will be nitrided to increase the hardenss.

It is important to keep maintenance for the bucket moulds. We should check and make sure the the water channels and air circuit unlocked.

3. Bucket Mould Cooling system

Cooling system design is a relatively cumbersome work, namely to consider the uniformity of the cooling and the cooling effect, also the impact brings to the overall mold structure, determining the exact location and size of the cooling system; and cooling for key positions such as moving plate or the inserts, side sliders as well as side cores;standard cooling element design and the selection of the cooling standard components.

Bucket cap mould

Product details

- Mould material: P20/718/738/NAK80/S136/2738/2316

- Mould base: LKM Standard

- Product Material: HDPE,PP,PS,PC,POM,ABS,NYLON,ETC

- Design software: PROE,CAD,UG,SOLIDWORK

- Cavity: Multi Cavity,single cavity

- Surface treatment: Polish. Etched. Texture

- Mould life: 300000-3000000shots

- Runner: Hot Runner Cold Runner

- Cooling system: In core baffle and in cavity plate chain drilling type cooling

- Ejection system: Motor/hydraulic cylinder/stripping plate/angle pin,etc

- Product Keywords: High Quality 10L Plastic Paint Bucket Cover Mould

Bucket mould Sealing perfermance testing

Bucket mould strength pferfermance test

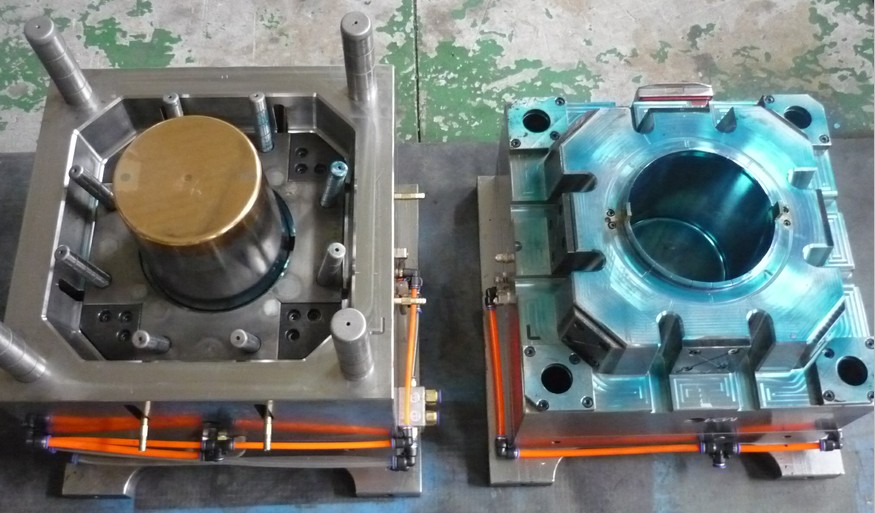

Bucket mould making

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

- Can paint buckets be used for food

- Common manufacturing process of making antifreeze buckets mould

- Four factors affecting the sealability of waterproof coating bucket mould

- plastic chemical bucket customization factory in Taizhou of China

- Six standards for testing the quality of antifreeze bucket mould

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould

Hot tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker,customized