CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

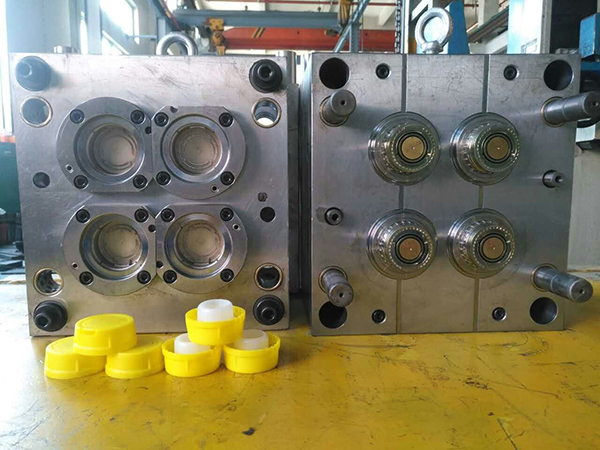

Design of Multi-cavity Injection Bottle Cap Mould

2019-12-20

Bottle cap hot runner system is generally a multi-cavity injection bottle cap mold, which requires high product balance and requires a balanced design. The temperature control between the nozzles must be accurate and the temperature difference should be within the allowable range.

Aiming at the characteristics of the cap hot runner, the hot constant hot runner adopts a balanced structure design to meet the user's requirements. At present, the cap hot mold hot runner system is on sale.

Each system of hot constant hot runner system is carefully tailored, and different materials are used for processing according to different products.

The characteristics of the bottle cap mold are as follows:

- 1. Multi-cavity points: from 4 to 96 cavities have mature technology, the simplified hot runner is reliable and low cost;

- 2, high efficiency: Simplified dispensing hot runner, no glue waste, cycle time is 5 seconds;

- 3, high life: cavity is made of high quality mold steel, heat treated HRC52, key core parts can reach HRC60, mold guide column guide The sleeve adopts oil-free lubrication method, no pollution, and the service life can reach ten million times;

- 4. Special design of the knife edge: The split ring knife edge adopts a split structure, the blade does not deform, the positioning is accurate and easy to replace, and the mold is not touch Pressure, long service life, overcoming the shortcomings of poor positioning accuracy of the overall blade, easy to run, easy to damage, short life;

- 5. high product quality and low cost: beautiful glue mouth, accurate size, water seal, screw break Force, strength, all meet the quality standard requirements, and the product is lightweight, reducing the cost of materials by 5%. Taizhou Changping Betop Precision Mould Factory

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

- Description of the characteristics of the plastic bottle cap market

- Features of plastic bottle cap mold

- Introduction of the advantages of plastic bottle cap mould

- The impact of plastic cap materials on the mold

- The importance of temperature control of plastic bottle caps mold

- Raw material analysis of plastic bottle cap products

- Considerations for the design of plastic bottle cap moulds

- Analysis of plastic bottle threads cap mould

- The impact of plastic cap materials on the mold shows that

- Technical parameters of the plastic cap mould

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould

Hot tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker,customized