In the process of plastic mold injection molding, temperature control is extremely important. It will not only affect the quality of the product but also its molding cycle. Different plastics have different fluidity, so their temperature control is also different. Plastics with good fluidity are generally controlled at about 60 ° C; plastics with poor fluidity are generally controlled between 80 ° C and 120 ° C. In addition, the cooling process of crystalline plastics and non-crystalline plastics is not the same. This point should be distinguished in the injection molding process.

During the injection molding process of plastic molds, if the temperature is too high, it will affect the uneven shrinkage of the molding and cause deformation of the mold products; if the temperature is too low, it will reduce its fluidity, resulting in defects or flow marks on the surface after molding. If the temperature of the mold is not uniform, the temperature after curing will be uneven, and stress will be generated, which will deform and crack the molded product. Therefore, the temperature control has a great impact on the shrinkage, stability, and quality of the product. We must pay special attention to plastic injection molding.

CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

The importance of temperature control of plastic bottle caps mold

2019-12-20

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

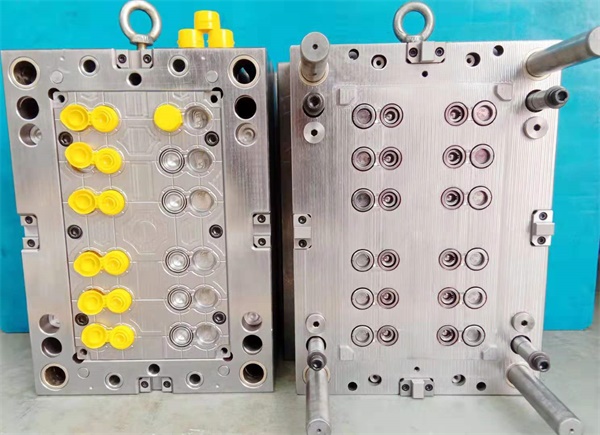

- Design of Multi-cavity Injection Bottle Cap Mould

- Description of the characteristics of the plastic bottle cap market

- Features of plastic bottle cap mold

- Introduction of the advantages of plastic bottle cap mould

- The impact of plastic cap materials on the mold

- Raw material analysis of plastic bottle cap products

- Considerations for the design of plastic bottle cap moulds

- Analysis of plastic bottle threads cap mould

- The impact of plastic cap materials on the mold shows that

- Technical parameters of the plastic cap mould

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould

Hot tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker,customized