CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

Structural design of beverage bottle cap mold

2019-12-20

According to the shape, accuracy, size, process requirements and production batch of plastic parts, the following aspects should be considered when designing the mold.

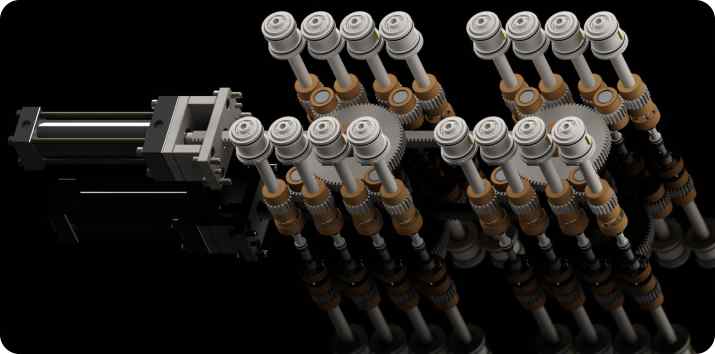

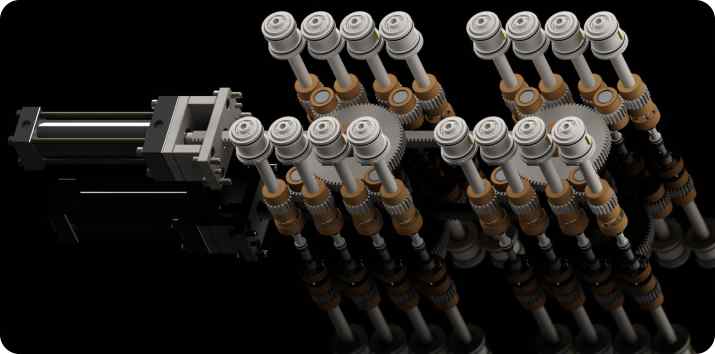

Number and arrangement of cavities: Bottle caps are used as packaging containers for mass production. One mold and multiple cavities should be used. Considering the clamping force of existing injection molding machines, injection volume, and accuracy and economic factors of bottle caps, it is determined as 1 mold 10 Cavities and cavities are arranged in a "figure".

Gating system design: According to the structure of the plastic part, the mold is designed as a three-plate type with a point gate. The gate is located at the center of the top of the plastic part. The point gate can significantly increase the shear rate of the melt and greatly reduce the melt viscosity. Conducive to mold filling, especially for melt-sensitive melts such as PE. And plastic parts as packaging containers have high appearance quality requirements and small residual traces at the gates, which can ensure the surface quality of the plastic parts. The gates are automatically broken when demolding, which facilitates the automation of product production processes and improves production efficiency. And increased economic benefits. The non-equilibrium casting system is adopted, the cavities are compactly arranged, and the size of the mold is reduced. In order to fill each cavity at the same time, the BGV (Balanced Gat Value) method is used to manually modify the size of each cavity gate to achieve balance. Use cold pockets to store forward cold stock.

Cooling system design: mold temperature adjustment system directly affects product quality and production efficiency. In order to improve the cooling efficiency of the cavity, a cooling circuit as shown in Fig. 2 is adopted, and the inlet of one circuit is located near the outlet of the other circuit; according to the shape of the plastic part and the structure of the mold, the diameter of the fixed mold cooling channel is φ12mm (see Figure 2 ), Connected with the out-of-mold hose to form circulating cooling. The diameter of the moving model core is relatively thin. The steel pipe cooling method is used. A soft copper core rod with good thermal conductivity is pressed in the center of the core, and one end of the core rod is extended into the cooling water hole for cooling.

Demolding mechanism design: The plastic part (bottle cap) has a semicircular coarse thread in the main part. The plastic part is made of polyethylene (PE), which has good flexibility. Consider using forced demoulding. In order to simplify the mold structure and reduce the mold Closing height, using a demoulding mechanism combining a limit plate and a pusher plate

Parting surface selection: The main body of the bottle cap is connected to the anti-counterfeit ring by only 8 small cylinders along the circumference, and two semi-circular huff blocks (lateral) are used to form the anti-counterfeit ring. Combined with the structural characteristics of the plastic part, the plastic part will inevitably remain on the core after molding, so the mold parting surface is set at the largest cross-sectional profile between the security ring and the body of the bottle cap, which is perpendicular to the mold opening direction.

Side core pulling mechanism: there is an anti-counterfeit ring in the lower part of the plastic part. The two huff blocks forming the anti-counterfeit ring and the main part of the bottle cap form a cavity, which is set in the fixed mold part. In the chute. When demolding, the inclined guide post pulls away the two Huff blocks to complete the side core pulling; when the mold is closed, the Huff blocks are locked by the wedge block mounted on the movable mold. Because the undercut of the formed anti-counterfeit ring is only 0.6mm, the The required pull-out force is not large, and the core-pulling distance is small. The Huff block is designed to always stay away from the oblique pin, so it is not necessary to set the Huff block positioning device.

Number and arrangement of cavities: Bottle caps are used as packaging containers for mass production. One mold and multiple cavities should be used. Considering the clamping force of existing injection molding machines, injection volume, and accuracy and economic factors of bottle caps, it is determined as 1 mold 10 Cavities and cavities are arranged in a "figure".

Gating system design: According to the structure of the plastic part, the mold is designed as a three-plate type with a point gate. The gate is located at the center of the top of the plastic part. The point gate can significantly increase the shear rate of the melt and greatly reduce the melt viscosity. Conducive to mold filling, especially for melt-sensitive melts such as PE. And plastic parts as packaging containers have high appearance quality requirements and small residual traces at the gates, which can ensure the surface quality of the plastic parts. The gates are automatically broken when demolding, which facilitates the automation of product production processes and improves production efficiency. And increased economic benefits. The non-equilibrium casting system is adopted, the cavities are compactly arranged, and the size of the mold is reduced. In order to fill each cavity at the same time, the BGV (Balanced Gat Value) method is used to manually modify the size of each cavity gate to achieve balance. Use cold pockets to store forward cold stock.

Cooling system design: mold temperature adjustment system directly affects product quality and production efficiency. In order to improve the cooling efficiency of the cavity, a cooling circuit as shown in Fig. 2 is adopted, and the inlet of one circuit is located near the outlet of the other circuit; according to the shape of the plastic part and the structure of the mold, the diameter of the fixed mold cooling channel is φ12mm (see Figure 2 ), Connected with the out-of-mold hose to form circulating cooling. The diameter of the moving model core is relatively thin. The steel pipe cooling method is used. A soft copper core rod with good thermal conductivity is pressed in the center of the core, and one end of the core rod is extended into the cooling water hole for cooling.

Demolding mechanism design: The plastic part (bottle cap) has a semicircular coarse thread in the main part. The plastic part is made of polyethylene (PE), which has good flexibility. Consider using forced demoulding. In order to simplify the mold structure and reduce the mold Closing height, using a demoulding mechanism combining a limit plate and a pusher plate

Parting surface selection: The main body of the bottle cap is connected to the anti-counterfeit ring by only 8 small cylinders along the circumference, and two semi-circular huff blocks (lateral) are used to form the anti-counterfeit ring. Combined with the structural characteristics of the plastic part, the plastic part will inevitably remain on the core after molding, so the mold parting surface is set at the largest cross-sectional profile between the security ring and the body of the bottle cap, which is perpendicular to the mold opening direction.

Side core pulling mechanism: there is an anti-counterfeit ring in the lower part of the plastic part. The two huff blocks forming the anti-counterfeit ring and the main part of the bottle cap form a cavity, which is set in the fixed mold part. In the chute. When demolding, the inclined guide post pulls away the two Huff blocks to complete the side core pulling; when the mold is closed, the Huff blocks are locked by the wedge block mounted on the movable mold. Because the undercut of the formed anti-counterfeit ring is only 0.6mm, the The required pull-out force is not large, and the core-pulling distance is small. The Huff block is designed to always stay away from the oblique pin, so it is not necessary to set the Huff block positioning device.

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

- Design of Multi-cavity Injection Bottle Cap Mould

- Description of the characteristics of the plastic bottle cap market

- Features of plastic bottle cap mold

- Introduction of the advantages of plastic bottle cap mould

- The impact of plastic cap materials on the mold

- The importance of temperature control of plastic bottle caps mold

- Raw material analysis of plastic bottle cap products

- Considerations for the design of plastic bottle cap moulds

- Analysis of plastic bottle threads cap mould

- The impact of plastic cap materials on the mold shows that

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould

Hot tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker,customized