CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

How To extend the life of the mold

2019-11-16

To prolong the service life of the mold, the optimization of the heat treatment process is very important. The main factors affecting the quality of the heat treatment are heating speed, quenching temperature, cooling rate and tempering temperature. After analysis and practice, the following heat treatment process is suitable for general enterprises, which can meet the mechanical performance requirements of 4Cr5MoSiV steel at high temperature.

-

1. Preheat.

-

2. Quenching.

-

3. Tempering.

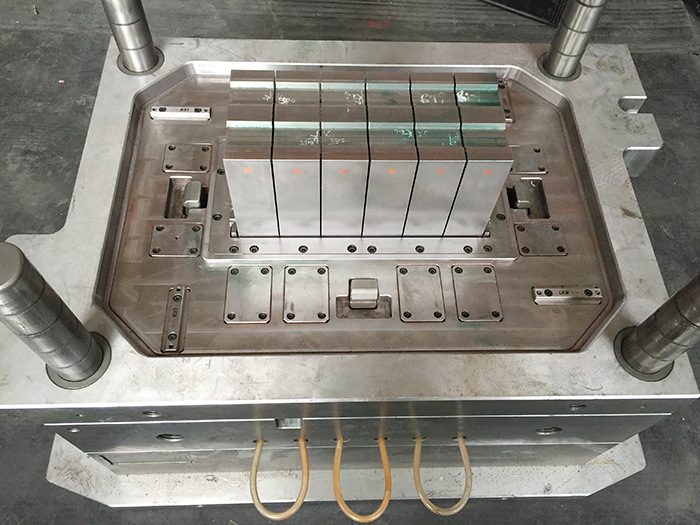

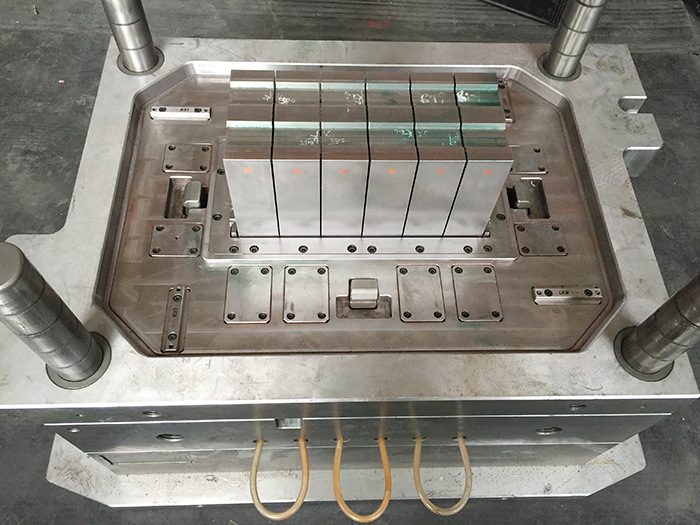

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould

Hot tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker,customized