CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

5 factors affecting the life of injection molds

2019-12-23

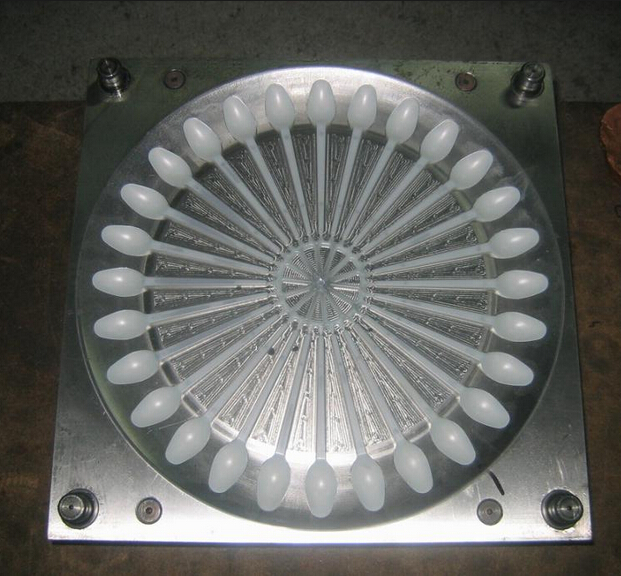

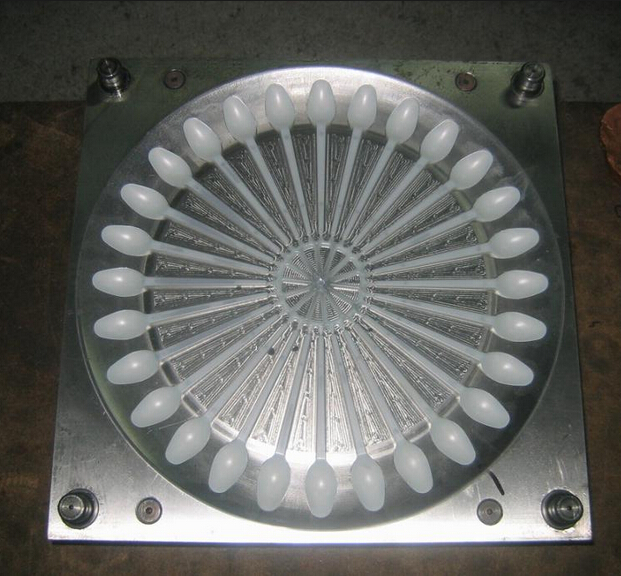

The injection mold is widely used in the processing of injection products. The quality of the injection mold is related to the quality of the finished product. The service life of the injection mold is important to ensure the quality of the product. , And will cause huge waste of costs such as mold materials, plastic processing time. So it is necessary to understand what factors affect the service life of injection molds?

1. Plastic raw materials. The selection of good plastic raw materials is conducive to the molding of the product and the improvement of the mold life.

2. Structural design of the mold.

3. Mold material and heat treatment. The better the material, the longer the service life of the mold, and the strict control of the heat treatment process, the impact on the mold life is also very large.

4. Mold processing and surface treatment.

5. Mould use and maintenance. Whether the mold is used and maintained properly is also an important factor.

There are many factors that affect the life of injection molds. In order to increase the life of injection molds, it is necessary to work hard and take measures on the five issues raised above. A long-life injection mold must meet the following characteristics: excellent structural design, excellent raw materials, reasonable heat treatment and processing methods, and correct use and maintenance. By doing these points, you can greatly increase the service life of the mold, thereby saving you a large amount of mold replacement costs and giving you an advantage in market competition.

There are many factors that affect the life of injection molds. In order to increase the life of injection molds, it is necessary to work hard and take measures on the five issues raised above. A long-life injection mold must meet the following characteristics: excellent structural design, excellent raw materials, reasonable heat treatment and processing methods, and correct use and maintenance. By doing these points, you can greatly increase the service life of the mold, thereby saving you a large amount of mold replacement costs and giving you an advantage in market competition.

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

- how to improve auto interior mould life

- How does the injection mold solve the scorch problem with exhaust

- How To extend the life of the mold

- The most likely defects in the mold injection molding process

- Why plastic injection molding products have weld lines

- Injection mold repair steps and precautions

- Mold plating chrome treatment technology is good for mold life

- The secret of plastic injection molding process adjustment

- Manufacturing method of automobile thin-wall door panel injection mold

- Can the silicone be injection molding

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould

Hot tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker,customized