CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

Why plastic injection molding products have weld lines

2019-11-16

When the molten plastic meets in the cavity due to the intrusion of the insert hole, the area where the flow velocity is inconsistent, or the area where the filling flow is stopped, the linear weld line is generated because it cannot be completely fused. Others in the generation of gate injection mold will also be a natural fusion line, the strength of the weld line and other performance is very poor. The reason for the important reason is as follows:

1. Processing:

- (1) The injection pressure and the rate are too low, and the temperature of the barrel and the mold temperature are too low, so that the melt entering the mold is cooled prematurely and the weld line is formed.

- (2) When the injection pressure and rate are too high, a spray will occur and a weld line will appear.

- (3) The speed should be increased, and the back pressure will increase the viscosity of the plastic and the density will increase.

- (4) The plastic should be dried well, and the recycled material should be used less. If the amount of the release agent is too much or the quality is not good, the weld line will appear.

- (5) Low clamping force to facilitate exhaust.

2. Mold aspect:

- (1) If there are too many gates in the same cavity, the gates should be eliminated or symmetrically set, or only close to the weld line.

- (2) The exhaust system at the weld line is poor, and an exhaust system should be established.

- (3) If the sprue is too large and the size of the pouring system is not appropriate, the gate opening only controls the melt to move around the insert hole, or only the insert is used less.

- (4) If the wall thickness is too large, or the wall thickness is too thin, the wall thickness of the part should be symmetrical.

- (5) If necessary, a fusion well should be opened at the weld line to allow the weld line to leave the part.

-

3. Plastics:

- (1) Plastics with poor mobility or heat sensitivity should be added with lubricants and stabilizers.

- (2) The plastic contains a lot of impurities, and it is necessary to change the quality of the plastic when necessary.

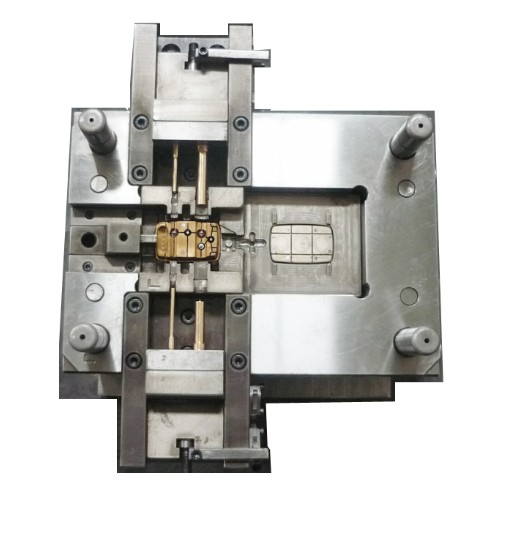

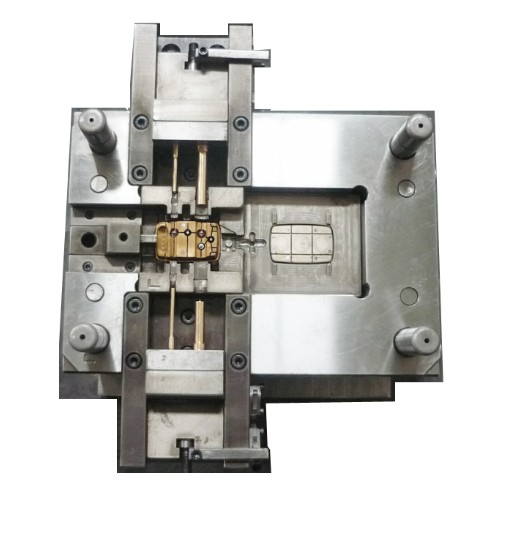

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

- How does the injection mold solve the scorch problem with exhaust

- How to solve common problems in plastic mold polishing

- injection problem-why welding line appears and how to solve it

- Why does the injection mold appear white? Injection mold problem of ejection white

- Analysis of common problems in injection molds

- what are the common problem in the plastic mould injection process

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould

Hot tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker,customized