CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

injection problem-why welding line appears and how to solve it

In injection production process, products often have various quality defects, such as cracking, warping deformation, poor size, shrink marks, weld lines, color difference, flash, insufficient strength, gas traps and black spots. For a long time, designers have lacked scientific system analysis for causes of these problems, resulting in long blind adjustments and large waste of raw materials, but they cannot solve these problems, affecting quality and delivery time of products. In severe cases, it will cause large-volume returns and reduce competitiveness of enterprise.

To solve defects of product molding, it is not enough to rely on past experience, root cause of defect needs to be found. Now injection molding principle and process are briefly explained first, then causes of weld line of injection products are analyzed. Defects are solved by adjusting injection moulding process parameters and mold design optimization, and actual case is combined with simulation analysis.

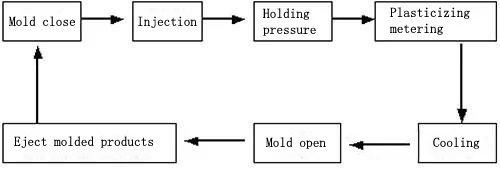

Figure 1 Complete injection molding cycle

Dried granular resin is sent to barrel equipped with heating device through hopper of injection molding machine to be heated and melted. Under push of screw, melt is injected into injection mold cavity by high speed and high pressure, melt is gradually solidified and shaped after a set time of pressure-holding cooling; mold is opened and molded products is extruded to complete a molding cycle. A complete injection molding cycle is shown in Figure 1.

Analysis of causes of weld lines

1 Fusion mark definition and formation conditions

Weld line is commonly referred to as a bond line, which means that when two or more streams of molten metal meet when molten plastic is filled into injection mold cavity, front portion of flowing melt has been cooled, so that it does not fuse well at the confluence to cause defects, as shown in picture 2.

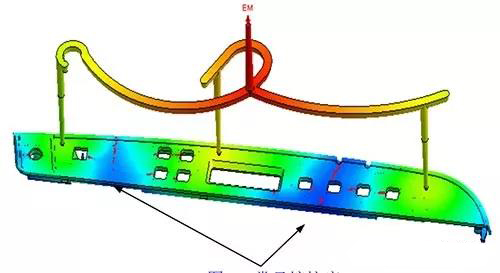

Figure 2 Common weld lines

Weld line on the part is like a scratch or a groove, especially at deep or transparent locations. Weld mark affects appearance quality and structural strength of product, and is liable to cause product to break.

When injecting a cavity, main conditions for molten plastic to merge and form a weld line are:

- 01 Determined by functional structure of product itself, such as various holes, grooves, inserts and uneven wall thickness.

- 02 Determined by mold design, such as number of gates, location, cooling system, and exhaust.

2 Weld mark type

Difference in product structure and different molding conditions in production process, mold making, form of weld lines are also different.

- 01 According to fusion depth of cross-section of weld line, it is divided into: surface-type weld line, that is, weld line only appears on the surface layer of product, which affects appearance quality of product and has little effect on structural strength of product; inner-layer weld line, weld line not only appear on surface layer, but also extends into inner layer of product, which affects appearance quality and structural strength of product; all through-type weld lines, that is, weld line runs through entire surface of product, seriously affecting structural strength of product and easily causing product to break.

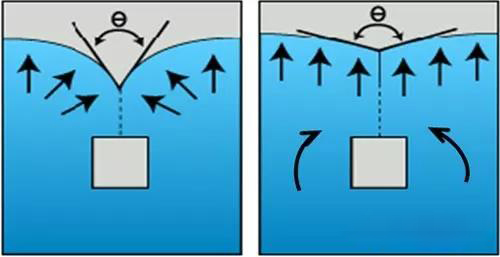

Figure 3 Stream front angle

- 02 According to process of forming weld line, it is divided into: encounter type weld line, molten plastic fills cavity from different gate positions, weld front face meets weld line formed at the front, and convergence angle of front edge of encounter type weld line is generally less than 135°, as shown in Fig. 3. Adjacent weld line is caused by structure of product. When filling, stream merges and forms a weld line. Convergence angle of two streams at leading edge of adjacent weld line is greater than 135°. Messy weld line has a fountain flow when melt is filled faster, and weld line has an irregular curve due to unstable flow.

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

- How does the injection mold solve the scorch problem with exhaust

- Why plastic injection molding products have weld lines

- How to solve common problems in plastic mold polishing

- Why does the injection mold appear white? Injection mold problem of ejection white

- Analysis of common problems in injection molds

- what are the common problem in the plastic mould injection process

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould