CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

Situation of plastic mold import and export of China

2019-12-06

According to relevant experts' predictions, this year's imported plastic molds in China will still be large-scale injection molds for cars and home appliances and plastic molds for integrated circuits, as well as multi-layer, multi-cavity, High-end and middle-end plastic molds, such as multi-materials and multi-color fine injection molds, are mainly used, and the export of molds may increase by more than 30%.

At present, China's mold imports are mainly from Japan, Taiwan and South Korea. According to export sources and import destinations, usually Guangdong, Jiangsu, Shanghai and Beijing have the largest number. The export destinations of China's molds are relatively scattered, mainly to Hong Kong SAR, Japan, the United States and Singapore. There are still many re-export trades during the way to Hong Kong. The large-scale application of plastics in life leads to the development of plastic molds much faster than other molds.

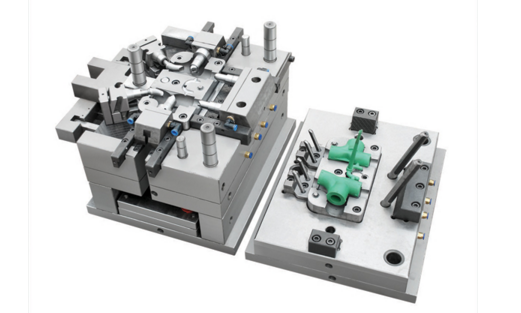

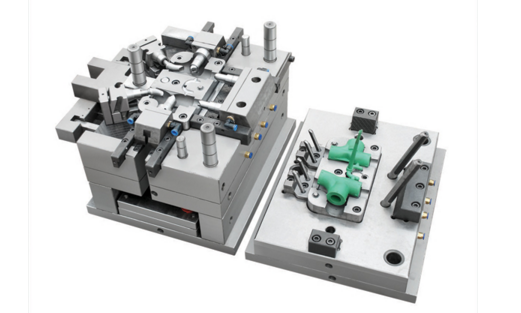

Nowadays, the injection molded plastic parts are getting larger and larger, and the increase in the demand for products has led to the need for a mold with multiple cavities, and some molds have to reach a mold with a cavity of 40 or a mold with a cavity of 50. The processing equipment is also getting larger and larger, and the accuracy requirements are getting higher and higher, and the hardness of the steel during mold processing is also increasing, which requires higher stability of the mold processing equipment.

For molds with complex product structures and multi-functional composite molds, with the complexity and diversification of product shapes, the design and manufacturing level of mold technicians must be improved, and multiple grooves and multiple materials in a set of molds are required. The processing of composite molds that are formed or assembled into components requires a large amount of programs during processing programming, a high level of processing and stability, and increased processing difficulty.

The user's precision requirements for plastic mold processing make the compounding, efficiency and high precision of processing equipment more attractive. Because of the advantages of high-speed milling, which can process hard mold materials, stable processing size, small cutting force, and small deformation when the workpiece is heated, so many companies attach great importance to it.

At present, China's mold imports are mainly from Japan, Taiwan and South Korea. According to export sources and import destinations, usually Guangdong, Jiangsu, Shanghai and Beijing have the largest number. The export destinations of China's molds are relatively scattered, mainly to Hong Kong SAR, Japan, the United States and Singapore. There are still many re-export trades during the way to Hong Kong. The large-scale application of plastics in life leads to the development of plastic molds much faster than other molds.

Nowadays, the injection molded plastic parts are getting larger and larger, and the increase in the demand for products has led to the need for a mold with multiple cavities, and some molds have to reach a mold with a cavity of 40 or a mold with a cavity of 50. The processing equipment is also getting larger and larger, and the accuracy requirements are getting higher and higher, and the hardness of the steel during mold processing is also increasing, which requires higher stability of the mold processing equipment.

For molds with complex product structures and multi-functional composite molds, with the complexity and diversification of product shapes, the design and manufacturing level of mold technicians must be improved, and multiple grooves and multiple materials in a set of molds are required. The processing of composite molds that are formed or assembled into components requires a large amount of programs during processing programming, a high level of processing and stability, and increased processing difficulty.

The user's precision requirements for plastic mold processing make the compounding, efficiency and high precision of processing equipment more attractive. Because of the advantages of high-speed milling, which can process hard mold materials, stable processing size, small cutting force, and small deformation when the workpiece is heated, so many companies attach great importance to it.

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

- China automotive mold manufacturing is facing the development trend of 2025

- How to find a good automotive mould supplier and manufacturer in China

- How to choose plastic mould supplier in Taizhou China

- China quality injection mould supplier how to make plastic mould

- Plastic mold maker,custom plastic molding maker in China

- High Medical mould supplier of China

- what is the price to make injection mould in China

- Chinese supplier of medical equipment mould

- How to choose a good quality injection mould manufacturer in China

- plastic chemical bucket customization factory in Taizhou of China

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould

Hot tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker,customized