CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

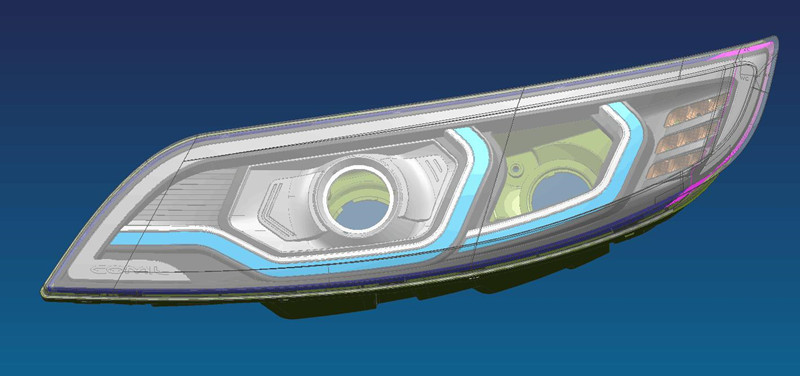

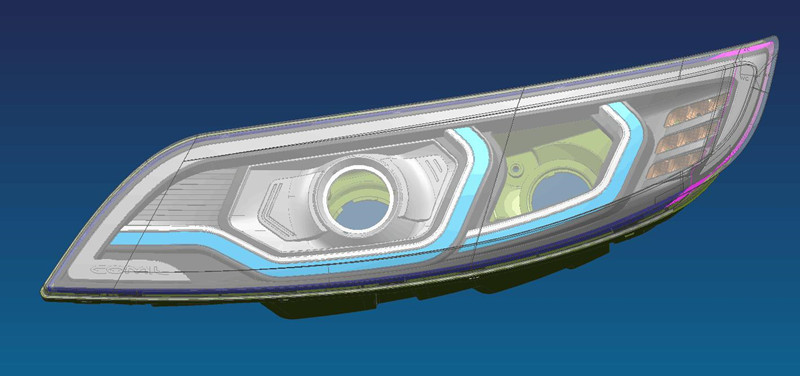

Explaining the forced release structure of car lamp mold

2019-12-28

In the lamp mold , the front mold often has an inverted buckle structure (for the lamp clamp wire). If the front mold row position or the front mold tilt is used, the mold structure will become complicated and unnecessary. Consider the following two types the way.

The case where there is no deformable space at the glue position buckle.

2. Structural characteristics:

① Advantages: It is safe and reliable. When the insert is under the action of the slingshot when the mold is opened, the product will be demoulded smoothly after the product's downturn part is completely exposed as the product moves to the next stage H.

② Disadvantages: The front mold structure is more complicated and takes up more space.

There is deformable space at the plastic buckle.

2. Structural characteristics:

① Advantages: All the buckles are made on the inserts. When the mold is opened, the product is forced out of the buckle by using the mold opening force and the characteristics of PP rubber, and the structure is simple.

② Advantages: The inserts receive screws on the surface for easy assembly and disassembly.

③ Disadvantages: The product has a chance to be towed, so it must be smooth.

First, the front die pin plate strong disengagement structure:

1. Scope of application:The case where there is no deformable space at the glue position buckle.

2. Structural characteristics:

① Advantages: It is safe and reliable. When the insert is under the action of the slingshot when the mold is opened, the product will be demoulded smoothly after the product's downturn part is completely exposed as the product moves to the next stage H.

② Disadvantages: The front mold structure is more complicated and takes up more space.

Second, the front mold inserts are strongly disengaged:

1. Scope of application:There is deformable space at the plastic buckle.

2. Structural characteristics:

① Advantages: All the buckles are made on the inserts. When the mold is opened, the product is forced out of the buckle by using the mold opening force and the characteristics of PP rubber, and the structure is simple.

② Advantages: The inserts receive screws on the surface for easy assembly and disassembly.

③ Disadvantages: The product has a chance to be towed, so it must be smooth.

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould

Hot tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker,customized