CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

Several methods commonly used to improve the performance of plastic molds

2019-12-13

The molds of Taizhou Plastic Mould Factory require the substrate to have a sufficiently high strength and toughness to cooperate reasonably, and its surface properties are very important to the working performance and service life of the mold. These surface properties refer to: wear resistance, corrosion resistance, friction coefficient, fatigue performance, etc. These performance improvements relying solely on the improvement and improvement of the base material are very limited and uneconomical. Through surface treatment technology, they can often get more results with less effort, which is why the surface treatment technology has developed rapidly.

Surface treatment of the injection mould

The surface treatment technology of the mold is a system engineering that changes the morphology, chemical composition, structure and stress state of the mold surface through surface coating, surface modification or composite treatment technology to obtain the required surface properties. From the way of surface treatment, it can be divided into: chemical method, physical method, physical chemical method and mechanical method. Although new treatment technologies are constantly emerging to improve the surface properties of molds, the main applications in mold manufacturing are nitriding, carburizing, and hardened film deposition.

Surface nitriding of the injection mould

Nitriding processes include gas nitriding, ion nitriding, and liquid nitriding. Each nitriding method has several nitriding technologies, which can meet the requirements of different steel types and different workpieces. Because the nitriding technology can form a surface with excellent performance, and the nitriding process and the quenching process of the mold steel have good coordination, at the same time, the nitriding temperature is low, no intense cooling is required after nitriding, and the mold deformation is extremely small. Surface strengthening is an earlier application of nitriding technology and is also the most widely used.

The purpose of carburizing of the mold is mainly to improve the overall strength and toughness of the mold, that is, the working surface of the mold has high strength and abrasion resistance. The technical idea introduced here is to use lower-level materials, that is, quenching by carburizing To replace higher grade materials, thereby reducing manufacturing costs.

Surface film hardened of the injection mould

At present, the hardened film deposition technology is more mature than CVD and PVD. In order to increase the bonding strength of the film surface, a variety of enhanced CVD and PVD technologies have been developed. The hardened film deposition technology was first applied to tools (knives, cutting tools, measuring tools, etc.) with excellent results. A variety of tools have adopted hardened film coating as a standard process. Since the 1980s, the mold has adopted the coating hardened film technology. Under the current technical conditions, the cost of hardened film deposition technology (mainly equipment) is relatively high, and it is still only applied to some precision, long-life molds. If a heat treatment center is established, the cost of hardened film coating will be greatly reduced. If more molds adopt this technology, the overall level of China's mold manufacturing can be improved.

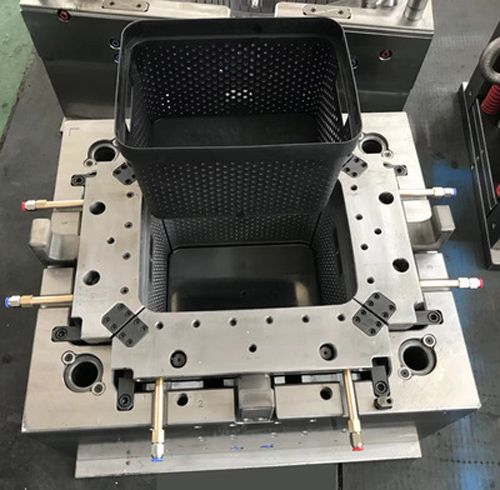

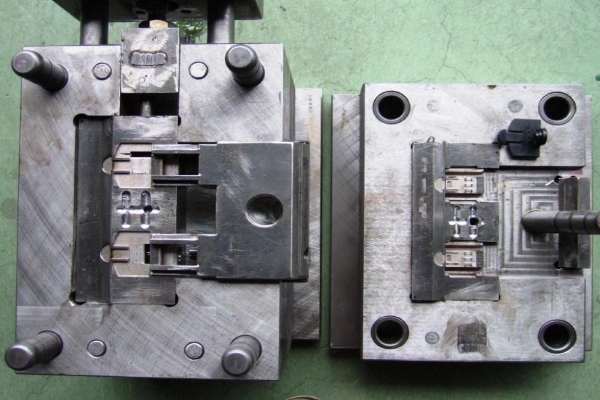

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

- Auto products mould manufacturer

- how to improve auto interior mould life

- China automotive mold manufacturing is facing the development trend of 2025

- What are the maintenance contents and steps of automotive molds

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- Which is good of Huangyan Automobile Mould Factory

- How does the injection mold solve the scorch problem with exhaust

- How to make the injection plastic mould gate design

- How To extend the life of the mold

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould

Hot tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker,customized