CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

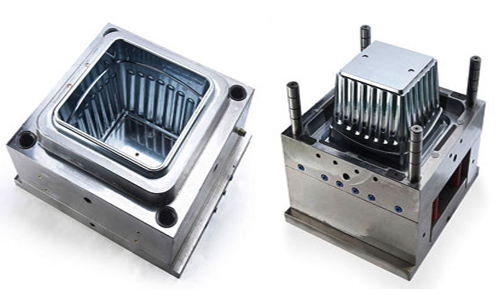

Several steps of injection mold processing

2019-12-23

If it is not the person who is engaged in the design and processing of injection molds , few people have a clear understanding of the steps of making injection molds. This article briefly introduces several steps in the process of making injection molds, hoping to help people who want to know.

1. The first is design preparation. After receiving the final drawing provided by the customer, the professional engineering staff will review the drawing in detail. If there are any problems, they will be raised and communicate with the customer for improvement! A larger mold factory will make a product PPT to the customer.

Before formal mold design, the following drawings or documents are usually available:

①, parts map;

②, mold design and production official book;

③ Design and make contract;

④, other

And we must fully understand the above information, and we need to get confirmation from the customer if it is not clear.

2. The next step is mold design, thimble design, row design, plastic inlet design, product processing process and so on. The general process of mold design work:

Initial review → Basic drawing design of molded products → Mold structure design → Part drawing design → Inspection drawing → Drawing

The design of the plastic injection mold starts from the design of the basic diagram of the molded product. Whether it is correct or not determines the quality of the molded product.

3. Order steel materials for the product. After the material comes back, a series of precision machining is performed, such as CNC, computer gong, wire cutting, sparking, grinding and polishing.

4. Assemble the injection mold. After completion, the engineer will check the mold, and then try the mold after there is no problem. The mold test is to check the condition of the mold and the structure of the plastic parts. Through the test mold, you can understand the situation of the mold in the beer making process and whether the structure is good. After the end of the test, the corresponding changes should be made according to the conditions of the test, and sent to the customer for confirmation after no problems.

In summary, the production process of injection molds mainly includes:

Accept tasks, mold design, mold manufacturing, processing procedures, mold inspection and test mold, mold modification and repair, mold maintenance.

Each of these links can be broken down into many steps. Interested partners can consult Changzhou Yitao Injection Mold Processing Co., Ltd. We are a company specializing in injection mold processing. The company has many years of mold production experience. The company provides high-quality and high-precision injection molding. We can design various types of injection molds according to the different needs of customers. Welcome friends to consult and negotiate.

Each of these links can be broken down into many steps. Interested partners can consult Changzhou Yitao Injection Mold Processing Co., Ltd. We are a company specializing in injection mold processing. The company has many years of mold production experience. The company provides high-quality and high-precision injection molding. We can design various types of injection molds according to the different needs of customers. Welcome friends to consult and negotiate.

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

- How does the injection mold solve the scorch problem with exhaust

- The most likely defects in the mold injection molding process

- Why plastic injection molding products have weld lines

- Injection mold repair steps and precautions

- The secret of plastic injection molding process adjustment

- Manufacturing method of automobile thin-wall door panel injection mold

- Can the silicone be injection molding

- plastic injection molding companies

- medical plastic injection molding company

- How to make quality medical injection molding producdts

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould

Hot tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker,customized