CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

Methods to identify high quality injection molds

2019-12-23

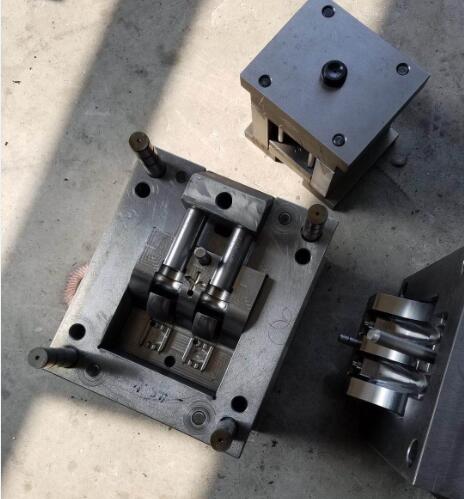

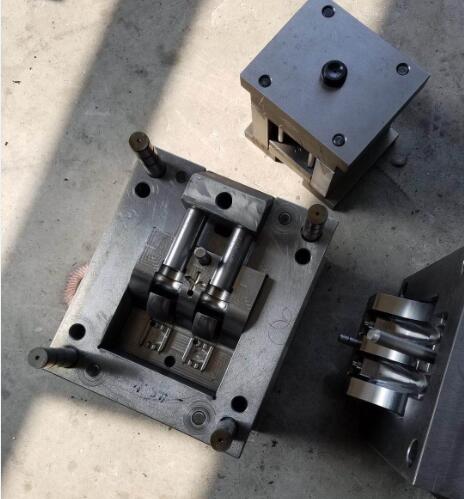

When customers are looking for a job to making injection molds, what they are most worried about is the processing quality of the injection molds. Generally, our molds are customized. Customers provide samples or drawings to the mold factory, and then the mold factory processes and produces them. For customers who are not particularly proficient in injection molds, how to identify high-quality injection molds is a difficult problem. Sometimes it seems that there is no problem with the mold itself, but the actual product produced by the mold may not be qualified. The identification is introduced below Quality mold method.

1. The polishing performance of the mold cavity surface must be excellent, so that the surface roughness value is minimized. Injection mold processing manufacturers should have good polishing workshops and equipment to ensure excellent polishing of the mold.

2. The mold must have good thermal stability. After the mold is quenched, the size of the mold must be kept basically unchanged. This is very strict on the process requirements of injection mold processing manufacturers.

3. The mold surface must have sufficient hardness and excellent wear resistance. This requires that the injection mold manufacturers have certain requirements for the selection of injection mold materials in the early stage.

In addition, the most important thing is to see if the size of the injection molded product is acceptable. If the product meets the requirements, it also depends on the yield of the product, such as a 10-die inspection or a 20-die inspection. If the scrap rate is high, the mold is still not qualified. You can also check the steel certificate of the mold, heat treatment certificate, and the supply information of the accessories. If you still have questions, please consult Changzhou injection mold processing , we are happy to help!

1. The polishing performance of the mold cavity surface must be excellent, so that the surface roughness value is minimized. Injection mold processing manufacturers should have good polishing workshops and equipment to ensure excellent polishing of the mold.

2. The mold must have good thermal stability. After the mold is quenched, the size of the mold must be kept basically unchanged. This is very strict on the process requirements of injection mold processing manufacturers.

3. The mold surface must have sufficient hardness and excellent wear resistance. This requires that the injection mold manufacturers have certain requirements for the selection of injection mold materials in the early stage.

In addition, the most important thing is to see if the size of the injection molded product is acceptable. If the product meets the requirements, it also depends on the yield of the product, such as a 10-die inspection or a 20-die inspection. If the scrap rate is high, the mold is still not qualified. You can also check the steel certificate of the mold, heat treatment certificate, and the supply information of the accessories. If you still have questions, please consult Changzhou injection mold processing , we are happy to help!

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

- How does the injection mold solve the scorch problem with exhaust

- The most likely defects in the mold injection molding process

- Why plastic injection molding products have weld lines

- Injection mold repair steps and precautions

- The secret of plastic injection molding process adjustment

- Manufacturing method of automobile thin-wall door panel injection mold

- Can the silicone be injection molding

- plastic injection molding companies

- medical plastic injection molding company

- How to make quality medical injection molding producdts

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould

Hot tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker,customized